Tin box usa is a professional tin box website owned by leading tin box manufacturer who focus on tin box manufacture and wholesale over 20 years. Here you can see many different types of tin boxes, here is the main page of metal tin box, as a leading tin box supplier all the tin box made by us are high quality, and all the customers order tin box from us can get high quality services, such as below is the detailed informations about our metal tin box, it can help you choose the righ metal tin box you need or like.

In order to let you know metal ton box clearly for your metal tin box wholesale, there is the Page Navigation about metal tin box.

What is a metal tin boxSpecifications of metal tin boxMaterial of metal tin boxFeatures of metal tin boxApplications of metal tin boxCustomization options for metal tin boxesSizes and shapes of metal tin boxesPrice range for metal tin boxesMaterials used in the production of metal tin boxesEnvironmental performance of metal tin boxesPrinting and branding options for metal tin boxesFreshness preservation capabilities of metal tin boxesProduction processes involved in making metal tin boxSustainability of metal tin boxesAdvantage of metal tin boxHow to make a metal tin boxHow to choose right metal tin boxTechnology in metal tin box manufacture |  |

Metal tin box is a container crafted from thin sheets of metal, typically tin-plated steel or aluminum. Renowned for its versatility, durability, and protective qualities, a metal tin box serves as a popular packaging solution for a diverse range of items. The construction of these boxes involves shaping and joining metal sheets into various forms, including rectangular or round containers.

A metal tin box is a container made of thin metal sheets, typically tin-plated steel or aluminum. It is commonly used for packaging various items due to its durability, versatility, and protective qualities.

Key Characteristics of Metal Tin Boxes:

|  |

Before you choose the metal tin box, you must know the detailed specifications about metal tin box, here is a detailed table outlining the specifications of a metal tin box provide by us for your metal tin box wholesale:

| Specification | Description |

|---|---|

| Material | Tin-plated steel or aluminum |

| Construction | Seam or spot welded, forming various shapes |

| Finish | Gloss or matte, customizable |

| Size Options | Various dimensions available based on product needs |

| Shape Options | Rectangular, round, square, cylindrical, etc. |

| Closure Types | Hinged, slip cover, screw-on, or plug-in closures |

| Printing/Embossing | Customizable with branding, logos, or embossed designs |

| Lining Material | Optional inner linings for specific contents |

| Coating | Clear or colored coatings for enhanced aesthetics |

| Usage Recommendations | Food-grade for edibles, corrosion-resistant for others |

| Recyclability | Typically recyclable, promoting sustainability |

These specifications provide a comprehensive overview of the key aspects of a metal tin box, ensuring that it meets specific requirements for various applications.

Metal tin boxes are primarily made from tin-plated steel or aluminum, ensuring a combination of strength and corrosion resistance.

| Applications of Metal Tin Box:Metal tin boxes find widespread applications in industries such as: Food Packaging: Ideal for storing and preserving a variety of food items. Gift Packaging: Often used for premium and decorative gift packaging. Cosmetics Packaging: Provides an elegant and protective solution for cosmetic products. Stationery Storage: Used for organizing and storing stationery items. Promotional Packaging: Popular for promotional giveaways and branding. |

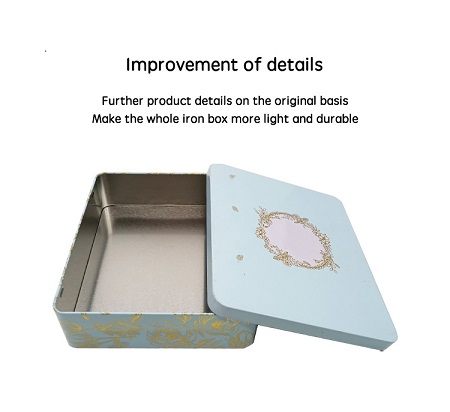

Durable and Sturdy Construction

Excellent Corrosion Resistance

Customizable Printing and Embossing Options

Versatile Shapes and Sizes

Recyclable and Environmentally Friendly

Metal tin box offer a range of customization possibilities:

Printing and Branding: Tin boxes can be customized with vibrant prints, logos, and branding, allowing businesses to create unique and recognizable packaging.

Shape and Size: Manufacturers provide flexibility in choosing the shape and size of metal tin boxes to suit the specific requirements of products.

Embossing and Debossing: Adding textured details through embossing or debossing enhances the visual appeal and branding of tin boxes.

Sizes and Shapes of Metal Tin Box:Metal tin boxes come in various sizes and shapes to accommodate different products: Rectangular Tins: Commonly used for packaging chocolates, biscuits, and other snacks. Round Tins: Suitable for items like tea leaves, coffee, or round-shaped products. Square Tins: Ideal for gifts and promotional items. Price Range for Metal Tin Boxes:The price of metal tin boxes can vary based on factors like size, customization, and order quantity. Generally, they offer a cost-effective packaging solution with options for different budget ranges. |  |

Metal tin boxes are typically made from tinplate, which is a thin steel sheet coated with a layer of tin. This material provides durability, corrosion resistance, and is suitable for food packaging.

Metal tin boxes are eco-friendly as they are recyclable. The recycling process of tinplate is efficient and helps reduce the environmental impact compared to some other packaging materials.

| Printing and Branding Options for Metal Tin Boxes:Metal tin boxes allow for various printing techniques, including lithography, embossing, and digital printing. This provides businesses with options to create visually appealing and branded packaging. Freshness Preservation Capabilities of Metal Tin Boxes:Metal tin boxes offer excellent freshness preservation, protecting contents from moisture, air, and light. This makes them suitable for storing perishable goods and maintaining product quality. |

The production of metal tin boxes involves several steps, including:

Cutting and Forming: Tinplate sheets are cut and formed into the desired shapes for the boxes.

Printing: Designs, logos, and other graphics are applied to the tinplate through various printing methods.

Embossing/Debossing: Texture or patterns may be added through embossing or debossing processes.

Assembly: Pieces are assembled, and the boxes are sealed to ensure proper closure.

Metal tin boxes contribute to sustainability through recyclability. The ability to recycle tinplate reduces the environmental impact and supports eco-friendly packaging solutions.

Advantages of Metal Tin Boxes:Content Protection: Metal tin boxes shield contents from light, moisture, and external elements, preserving their quality. Branding Opportunities: These boxes offer excellent surfaces for branding, labels, or embossing, enhancing product visibility. Long-lasting: Known for their durability, metal tin boxes can be reused and offer a longer product life. Environmentally Sustainable |  |

Finishing: Add closure mechanisms and any additional finishing touches.

Intended Use: Choose based on the specific requirements of the contents.

Modern manufacturing technologies involve advanced metal forming, cutting, and printing techniques, ensuring precision, efficiency, and high-quality production. Automated processes contribute to consistent results and increased production speed. Innovations in eco-friendly coatings and finishes align with sustainable manufacturing practices.

Q: What is the primary material used in manufacturing metal tin boxes?

Q: Are metal tin boxes environmentally friendly and recyclable?

Q: Can metal tin boxes be customized with unique designs or logos?

Q: What types of closures are available for metal tin boxes?

Q: Are there specific coatings available for metal tin boxes?

Q: Can metal tin boxes be used for food packaging?

Q: How can one choose the right size and shape for a metal tin box?

Q: Is the interior of metal tin boxes lined for specific contents?

Q: What is the typical finish for metal tin boxes?

Q: Are there specific recommendations for using metal tin boxes for certain products?

A: Yes, it's recommended to use food-grade metal tin boxes for edibles and corrosion-resistant ones for other products.