Tin box manufacturer provide all tin boxes manufacture and all tin can wholesale with modern tin box factory. We focus on tin box for sale over 20 years. tin box usa is the website related to high quality tin box, all the informations and pictures are high match to tin box, here you can see many different tin boxes, and order ant type tin box you need or like.

This page is the main page of tin box, as a leading tin box manufacturer we focus on providing good quality tin box to our customers, in order to let you know more about tin box clearly or choose the tin box quickly, below is the Page Navigation about our tin box.

| What is a tin box | What do you put in a tin box |

Specifications of tin box | What is the difference between a tin box and a tin can? | |

Classifications of our tin box | What is the use of tin box? | |

Price of tin box | What tin means? | |

Features of tin box | Can I use tin can for baking? | |

Material of tin box | Are tin boxes sustainable? | |

Advantages of tin box | What is the history of tin boxes? | |

How to make a tin box | Who owns tin box? | |

Applications of tin box | How are tin boxes printed? | |

When was tin box invented? | What are tin containers made of? |

What is the main features of tin box | Tin box applications |

Manufacturing process | Technology involved in the manufacture of tin boxes |

Tin box, also known as a tin container or tin can, is a type of packaging made of thin metal, usually tinplate or aluminum. It is characterized by its durability, resistance to corrosion, and ability to preserve the contents inside. Tin boxes come in various shapes and sizes, featuring a hinged or removable lid for easy access. These containers are commonly used for storing and packaging a wide range of items, including food, cosmetics, promotional products, and more.

What is the main features of tin boxThe main features of a tin box include its sturdiness, light weight, and versatility in design. The material used in its construction provides a protective barrier against external elements, ensuring the longevity of the enclosed contents. Tin boxes are often chosen for their aesthetic appeal, as they can be decorated with vibrant prints, embossing, or special finishes. Tin box applicationsApplications of tin boxes are diverse, spanning industries such as food and beverage, confectionery, gift packaging, and collectibles. The advantages of using tin boxes include their recyclability, stackability, and the ability to be customized to suit branding or promotional needs. |

|

| Manufacturing process of tin boxIn the manufacturing process, sheets of metal are shaped and formed into the desired tin box design. The boxes can be further decorated through printing, coating, or embossing techniques. When choosing a tin box, considerations may include size, shape, design, and intended use. Technology in manufacture of tin boxThe technology involved in the manufacture of tin boxes has evolved to ensure precision and efficiency. As a classic packaging solution, tin boxes continue to be a popular choice for various consumer products. The future of tin boxes may involve innovations in sustainable materials and eco-friendly production methods. |

For those looking to choose a tin box, factors such as the intended use, branding requirements, and environmental considerations should be taken into account. Overall, tin boxes remain a timeless and reliable packaging solution with a wide range of applications.

Who invented tin? | Is tin packaging recyclable? | Which country discovered tin? |

Where is tin originally from? | Is tin 100% recyclable? | Where is tin found in China? |

What country uses the most tin? | Does tin react with water? | Is tin an alloy? |

The term "tin" can have different meanings depending on the context:

Chemical Element:

Containers:

Slang:

Tinplate:

Tin Mining:

The meaning of "tin" is context-dependent, and its interpretation can vary based on the industry, application, or historical context in which the term is used.

Who invented tin?Is tin packaging recyclable?Which country discovered tin?Where is tin originally from?Is tin 100% recyclable?Where is tin found in China?What country uses the most tin?Does tin react with water?Is tin an alloy? |  |

Tin, as a chemical element, has been known to humanity since ancient times. It has been used by various cultures for different purposes, including creating alloys and making tools. The discovery of tin cannot be attributed to a single individual, as it was likely discovered independently by different cultures.

Yes, tin packaging, such as tin cans, is recyclable. The recycling process involves melting down the tin-coated steel or tinplate to recover the metal for reuse. Recycling tin packaging helps reduce waste and conserve resources.

Tin has been used since ancient times, and its discovery cannot be attributed to a specific country. However, tin mining has been historically significant in several regions, including Cornwall in the United Kingdom, Malaysia, Bolivia, and Indonesia.

Tin is a naturally occurring element and is found in various parts of the world. Historically, significant tin production has been associated with regions like Cornwall in the United Kingdom, known for its tin mines.

Yes, tin is 100% recyclable. Tin, when used in packaging materials like tinplate, can be recycled repeatedly without losing its properties. Recycling tin helps reduce the environmental impact and saves energy compared to producing new tin from raw materials.

Tin is found in various provinces in China, and the country has been a significant producer of tin. Yunnan and Guangxi are among the provinces known for tin production.

The demand for tin is global, and its usage is spread across various industries. China has been a major consumer and producer of tin, using it in electronics, packaging, and other applications. Other countries, including Indonesia, Malaysia, and Brazil, also play important roles in the tin market.

Tin itself does not react with water at room temperature. However, when exposed to air and moisture over time, tin can form a thin layer of tin oxide on its surface. This layer can provide some protection against further corrosion.

Tin is often used in the creation of alloys. One well-known alloy is bronze, which is a mixture of tin and copper. Another example is pewter, an alloy of tin with antimony, copper, or other metals. Tin's ability to form alloys with various metals makes it valuable in different industrial applications.

Tin box made by different specifications, before you order tin box you shoule know the detailed specifications, below is the table of specifications of tin box

| Specification | Details |

|---|---|

| Material | Tinplate or other metal alloys |

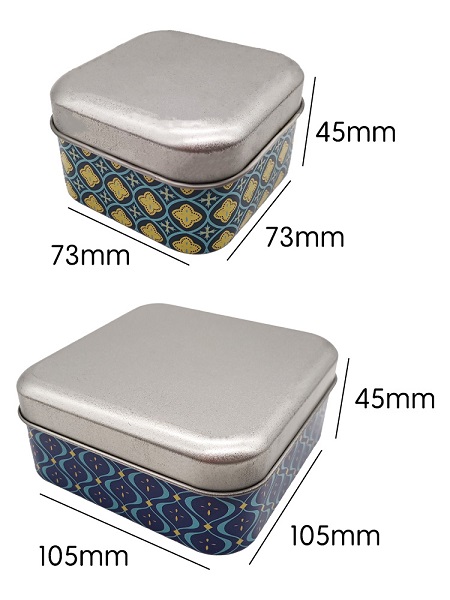

| Size | Various sizes and shapes available |

| Thickness | Customizable based on requirements |

| Surface Treatment | Rust-proof coating, printing, spray painting, etc. |

| Capacity | Varies based on size and shape |

| Shape | Square, round, rectangular, etc. |

| Color | Multiple color options available |

| Customization Options | Printing, engraving, spray coating, decorations, etc. |

| Usage | Packaging, gift boxes, storage containers, promotional items, etc. |

| Production Process | Stamping, welding, spray painting, bending, etc. |

| Environmental Impact | Considered with rust-proof coatings and recyclable materials |

| Printing Options | Full-color printing, embossing, debossing, lithography, etc. |

| Branding | Custom logos, labels, or embossing |

Lear more about the features and applications for your tin box wholesala, below is the detailed introduction to tin box features and applications provide by tin box manufacturer.

Features of Tin BoxTin box offers a myriad of features that make them a preferred packaging solution:

| Applications of Tin BoxesTin boxes find versatile applications across various industries:

|

| Advantages of tin boxTin boxes come with several advantages that make them a popular choice in the packaging industry:

Tin boxes combine practicality, aesthetics, and environmental considerations, making them a preferred choice for various industries and products. |

Custom tin box you like from us, here are many different types of tin boxes you can custom from us

| Type | Description |

|---|---|

| Hinged Lid Tin | Tin box with a hinged lid for easy access. |

| Sliding Lid Tin | Tin box with a sliding lid mechanism. |

| Window Lid Tin | Tin box featuring a transparent window on the lid. |

| Round Tin | Circular-shaped tin box. |

| Rectangular Tin | Tin box with a rectangular shape. |

| Nested Tin Set | Set of tin boxes that fit within each other. |

| Decorative Tin | Tin boxes with intricate designs and decorations. |

| Handle Tin | Tin box equipped with a handle for portability. |

| Type | Features | Customization Options | Applications |

|---|---|---|---|

| Metal Tin Box | Durable, versatile, various sizes | Printing, embossing, coatings | Packaging, gifts, promotions, storage |

| Custom Tin Box | Tailored design, branding | Printing, shape, size adjustments | Brand promotions, product packaging |

| Tin Box with Lid | Hinged or removable lids | Printing, embossing, decorations | Storage, gifts, keepsakes, packaging |

| Tin Lunch Box | Designed for carrying meals | Printing, color options | Food packaging, lunch containers, promotions |

| Size | Dimensions |

|---|---|

| Small | 2 inches x 2 inches |

| Medium | 4 inches x 4 inches |

| Large | 6 inches x 6 inches |

| Extra Large | 8 inches x 8 inches |

| Customized | Tailored to specific dimensions based on requirements. |

| Type | Size | Price Range |

|---|---|---|

| Hinged Lid Tin | Medium | $2.50 - $5.00 |

| Round Tin | Small | $1.00 - $2.50 |

| Decorative Tin | Large | $5.00 - $10.00 |

| Nested Tin Set | Set of 3 | $8.00 - $15.00 |

Some inportant questions about Tin box you should know

1. When was tin box invented?The concept of using tin for packaging dates back to the early 19th century. The first mass-produced tin boxes emerged in the 1810s in England, and they gained popularity for storing a variety of goods due to their durability and ability to preserve contents. 2. What do you put in a tin box?Tin boxes are versatile and can be used to store a wide range of items. Common uses include: Food Items: Chocolates, candies, cookies, tea leaves, and coffee. Personal Items: Jewelry, mementos, keepsakes, and small accessories. Gift Packaging: Tin boxes are often used as decorative gift packaging for special occasions. Promotional Products: Companies use custom tin boxes for branding and promotional purposes. | 3. What is the difference between a tin box and a tin can?The primary difference lies in their form and purpose: Tin Box: Typically has a rectangular or square shape with a hinged or removable lid. Often used for decorative or promotional packaging. Tin Can: Usually cylindrical with a sealed top. Commonly used for preserving and packaging food items, beverages, or industrial products. 4. What is the use of tin box?Tin boxes serve various purposes, including: Packaging: Protecting and preserving contents due to the non-reactive nature of tin. Gifts and Souvenirs: Often used for presenting gifts or creating commemorative items. Promotion: Customized tin boxes are utilized for branding and promotional campaigns. Storage: Ideal for storing small items, accessories, and keepsakes. | 5. Can I use tin can for baking?Tin cans are generally not recommended for baking. While they are made of metal, the inner lining of many tin cans may contain substances that are not safe for direct contact with food during baking. It's safer to use designated bakeware for cooking or baking. 6. Are tin boxes sustainable?Tin boxes are considered relatively sustainable due to the recyclability of tin. They can be recycled repeatedly without losing quality. Additionally, tin is abundant and easily extracted, making it an environmentally friendly choice. |

The history of tin boxes traces back to the early 19th century in England, where the first mass-produced tin boxes were created. Initially used for storing tea, they gained popularity for various goods. The advent of lithography in the mid-19th century allowed for colorful and intricate designs, further boosting their appeal.

Tin boxes are produced by various manufacturers and can be owned by individuals, companies, or collectors. Ownership is not typically centralized to a specific entity.

Tin boxes are printed using various methods, including:

Offset Printing: Common for high-quality and detailed designs.

Lithography: Utilizes the principle of oil and water to transfer images onto the tin surface.

Digital Printing: Directly transfers digital images onto tin for shorter print runs.

Tin containers are often made of tinplate, which is a thin sheet of steel coated with a layer of tin. This combination provides the strength of steel and the corrosion resistance of tin, making it suitable for various packaging applications.

Understanding the history, uses, and printing processes of tin boxes contributes to their widespread appeal and diverse applications in contemporary settings.

The process of making tin boxes involves several steps, including material preparation, shaping, decorating, and finishing. Here is an overview of how tin boxes are typically made:

Material Selection:

Sheet Cutting:

Forming:

Welding or Soldering:

Surface Treatment:

Decoration:

Finishing:

Quality Control:

Packaging:

Customization (Optional):

It's important to note that the specific steps in the manufacturing process can vary depending on the complexity of the tin box design and the intended use. Manufacturers may use advanced technologies and automation to ensure precision and efficiency in the production of tin boxes.

Choosing the right tin box involves considering various factors to ensure that it meets your specific needs and preferences. Here are key aspects to consider when selecting a tin box:

Purpose and Usage:

Size and Dimensions:

Material and Coating:

Closure Mechanism:

Decoration and Branding:

Color and Finish:

Quality and Durability:

Environmental Impact:

Customization Options:

Budget:

By carefully considering these factors, you can choose a tin box that not only serves its practical purpose but also aligns with your branding and aesthetic preferences.

Printing and technology are very important for your custom tin box, when you choose tin box you should learn more about the printing and technology of tin box, below is the detailed informations about tin box.

Printing of Tin BoxPrinting on tin boxes is a crucial step in customization, allowing brands to showcase logos, designs, and information. Different printing methods are employed to achieve various effects on the tin surface. Printing Methods:

| Technology of Tin BoxManufacturing Process:

Technological Innovations:

Understanding the printing techniques and manufacturing processes is crucial for achieving the desired visual appeal and functionality in tin box production. The combination of traditional craftsmanship and modern technologies contributes to the high-quality standards in the industry. |

Quality: Strict quality control measures to ensure durable and reliable tin boxes.

Choosing a specific supplier or manufacturer for tin boxes involves evaluating various factors that set them apart from others in the market. Here are several reasons why you might choose a particular provider for tin boxes:

Expertise and Experience:

Customization Capabilities:

Quality Assurance:

Diverse Product Range:

Innovative Technology:

Sustainability Practices:

Reliability and Consistency:

Competitive Pricing:

Customer Reviews and Testimonials:

Customer Support:

When selecting a supplier for tin boxes, it's essential to weigh these factors based on your specific requirements and priorities. Conduct thorough research, ask for samples, and communicate directly with potential suppliers to make an informed decision that aligns with your business goals.

Are tin boxes food-safe?

Can I get a custom design for my tin box?

Is there a minimum order quantity for customized tin boxes?

Are your tin boxes suitable for international shipping?

How do I clean and maintain my tin box?

Do you offer eco-friendly packaging options?

What printing methods do you use for customization?

Are your tin boxes suitable for long-term storage?

Can you provide samples before placing a bulk order?

What is the average lead time for bulk orders?