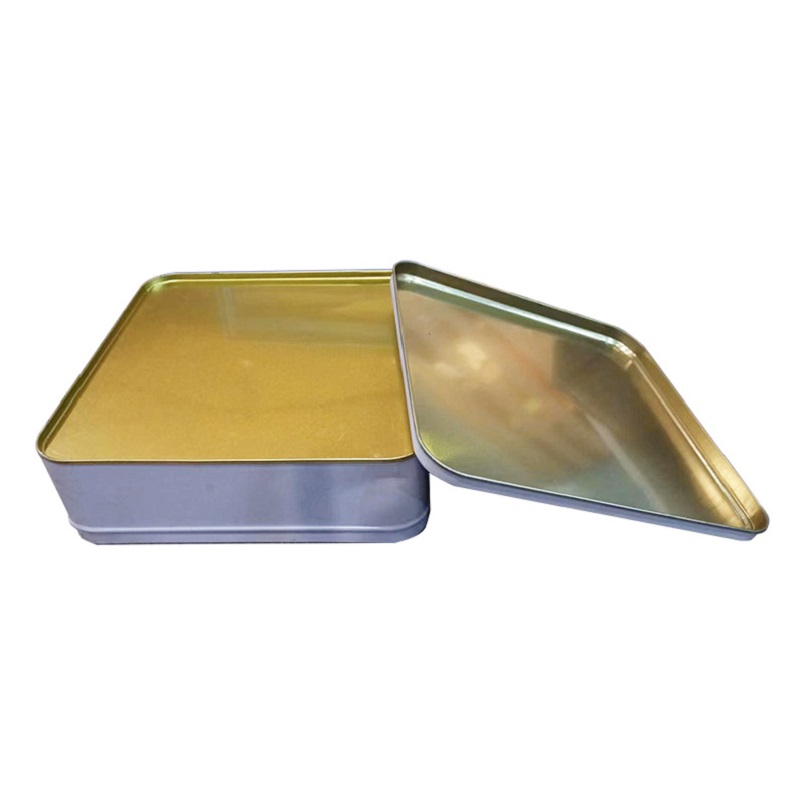

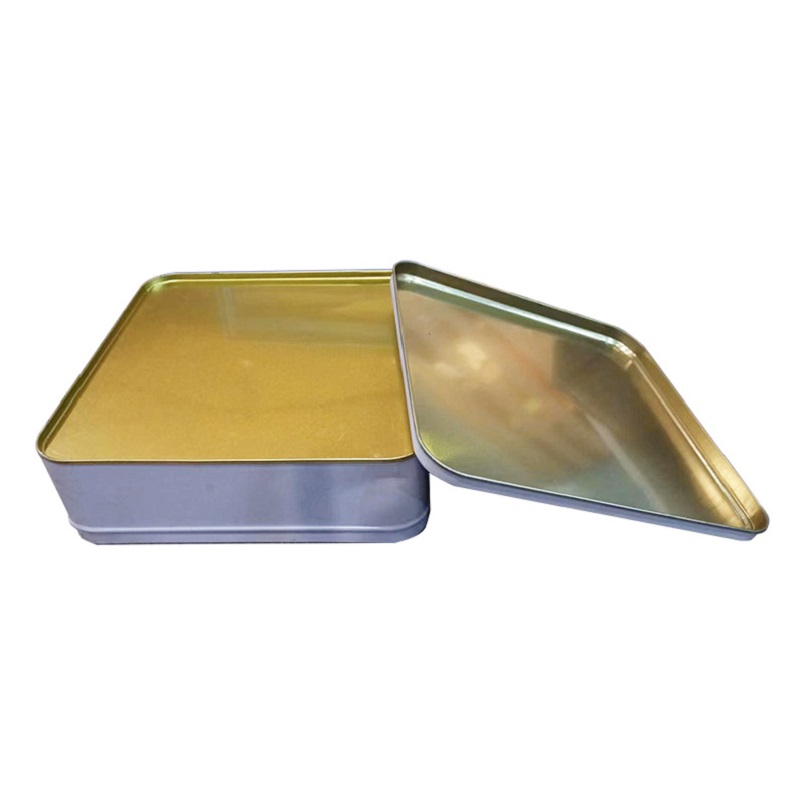

Tin lunch box

Tin lunch box is one sample of our tin box which is a container typically made from tinplate, a type of steel coated with a thin layer of tin to prevent corrosion. These lunch boxes are designed for carrying meals, snacks, or other items in a secure and stylish manner. They often feature a hinged lid and a handle for easy carrying. Tin lunch boxes have been popular for many years and are known for their durability and retro charm.

Key Features of Tin Lunch Box:- Material: Tinplate or other metal alloys.

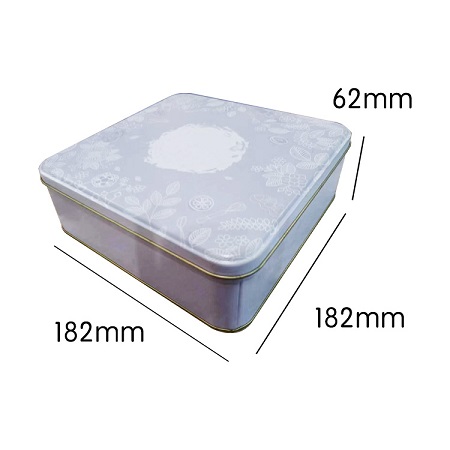

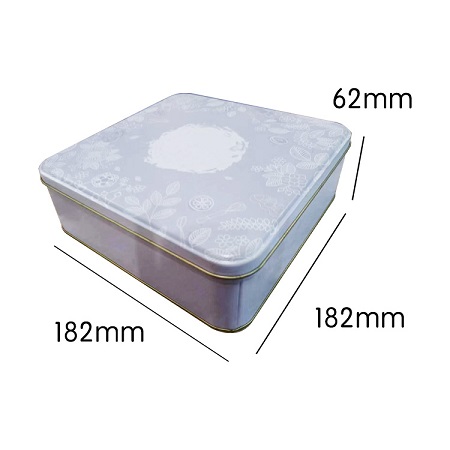

- Size: Various sizes available to accommodate different needs.

- Shape: Typically rectangular or square, but can vary.

- Design: Can be plain or decorated with colorful prints, patterns, or images.

- Closure: Hinged lid with a latch or clasp for secure closure.

- Handle: Many designs include a handle for easy carrying.

- Customization: Often customizable with personalized prints or branding.

- Durability: Sturdy construction for protection of contents.

- Versatility: Suitable for carrying lunches, snacks, or small items.

- Collectible: Some tin lunch boxes are designed as collector's items due to nostalgic or themed designs.

|  |

Welcome to tin box usa which is a professional tin box website owned by a profession tin box manufacturer who focus on tin box wholesale over 20 years, As a leading tin box supplier we have our own tin box factory. Here you can see many different types of tin boxes, this page is main related to tin lunch box which is one sample of our tin box, before you order tin lunch box, you should lear more about it, below is the detailed introduction to our tin lunch box.

Specifications:

| Specification | Details |

|---|

| Material | Tinplate or other metal alloys |

| Size | Various sizes available |

| Types | Traditional, compartmentalized, themed, etc. |

| Shapes | Rectangular, square, cylindrical, etc. |

| Market Price Range | Varies based on size, design, and features |

Sizes of Tin Lunch Box:

| Size | Dimensions | Ideal Use |

|---|

| Small | 6" x 4" x 2" | Snacks, light meals |

| Medium | 8" x 6" x 3" | Regular lunch portions |

| Large | 10" x 8" x 4" | Family-sized meals |

This is some sample size, if you are interesting we will custom any size for you.

Types of Tin Lunch Box:

- Traditional: Classic designs with a retro feel.

- Compartmentalized: Sections for separating different food items.

Themed: Showcasing characters, logos, or specific themes.

Shapes of Tin Lunch Box:

- Rectangular: Standard shape suitable for most lunch items.

- Square: Compact and easy to carry, ideal for shorter trips.

Cylindrical: Unique design catering to specific preferences.

Market Price Range:

Prices vary based on size, design intricacy, and customization options, ranging from $5 to $30.

Market Price Range of Tin Lunch Boxes:

| Size (inches) | Design/Print Complexity | Material | Price Range ($) |

|---|

| 7x5 | Simple | Tinplate | 5 - 10 |

| 9x6 | Moderate | Tinplate | 8 - 15 |

| 10x7 | Intricate | Tinplate | 12 - 20 |

| Custom | Customized | Tinplate | Variable |

Note: Prices are indicative and may vary based on factors like design intricacy, customization, and additional features.

This table provides a general overview of the market price range for tin lunch boxes based on size, design complexity, and material. Actual prices may vary depending on specific requirements and market conditions.

|

Applications of Tin Lunch Boxes:- Lunch Carrier: Ideal for carrying meals to school, work, or picnics.

- Storage: Can be used to store small items or keepsakes.

- Collectibles: Some tin lunch boxes are sought after by collectors.

- Promotional Items: Customized with logos or designs for promotional purposes.

Advantages of Tin Lunch Boxes:- Durable and long-lasting.

- Retro and nostalgic appeal.

- Customizable for personal or promotional use.

- Environmentally friendly if made from recyclable materials.

|

How to Make a Tin Lunch Box:

- Material Preparation: Cut tinplate sheets to the desired size.

- Forming the Body: Use machinery to shape the tin into the desired box shape.

- Attaching the Lid: Hinge the lid to the body using hinges or a similar mechanism.

- Adding Handle: Attach a handle for easy carrying.

- Decoration: Apply prints or patterns using printing or embossing techniques.

Finishing: Apply coatings for rust resistance and aesthetic finish.

How to Choose a Tin Lunch Box:- Size: Consider the capacity needed for your meals.

- Design: Choose a design that fits your style or preferences.

- Durability: Look for sturdy construction and quality materials.

- Customization: If you want a personalized touch, opt for customizable options.

Purpose: Consider whether it's for daily use, special occasions, or collecting.

Why Choose Tin Lunch Boxes:- Durable Construction: Tin boxes are known for their durability.

- Customization: Personalize your lunch box with unique designs.

- Retro Charm: Tin lunch boxes often have a nostalgic and vintage appeal.

- Environmentally Friendly: Recyclable materials contribute to sustainability.

|  |

Printing of tin lunch box:

Custom printing options allow for personalization with logos, characters, or themes, adding a unique touch to each lunch box.

Printing of Tin Lunch Boxes:

Printing on tin lunch box is a crucial aspect that allows for customization and branding. Here are key points related to the printing of tin lunch boxes:

Printing Technologies:

- Offset Printing: Commonly used for high-quality, detailed designs.

- Lithography: Ideal for large quantities with consistent and vibrant prints.

- Digital Printing: Suitable for short runs and intricate designs.

Color Options:

- Full-color printing is standard, offering a wide spectrum for vibrant designs.

- Limited color palette for specific branding or vintage aesthetics.

Printing Surfaces:

- Flat surfaces allow for precise and detailed printing.

- Embossing or debossing can be incorporated for added texture.

Customization:

- Logos, graphics, and text can be customized according to brand requirements.

- Full-wrap printing or selective areas can be chosen for branding.

Design Considerations:

- Design should consider the curved or rounded nature of tin lunch boxes.

- Graphics should be adapted to fit the shape without distortion.

Finish Options:

- Matte or gloss finishes can be applied to enhance the visual appeal.

- Spot UV coating for highlighting specific design elements.

Durability:

- Printing should be durable and resistant to scratches or abrasions.

- Consideration for food-safe printing in cases of direct contact with edibles.

Regulatory Compliance:

- Ensure that the printing process adheres to relevant food safety regulations.

Environmental Impact:

- Choose eco-friendly printing options to align with sustainability goals.

Quality Control:

- Rigorous quality checks to maintain consistency and accuracy in prints.

Customizing the printing process allows businesses to create visually appealing tin lunch boxes that effectively communicate brand identity and product information. It's crucial to work with experienced manufacturers to achieve high-quality and durable prints.

Technology in tin lunch box manufacturing:

Manufactured using advanced technologies such as stamping, welding, and printing to ensure durability, functionality, and aesthetic appeal.

The manufacturing of tin lunch boxes involves various technologies to ensure precision, efficiency, and quality. Here are key aspects of the technology used in tin lunch box production:

Metal Forming:

- Stamping and Die-cutting: Utilized to cut and shape tin sheets into the desired form.

- Deep Drawing: Involves forming three-dimensional shapes from flat sheets.

Material Preparation:

- Tinplate Coating: Sheets of steel are coated with a layer of tin to prevent corrosion.

- Sheet Cutting: Tin-coated sheets are cut into specific sizes for the manufacturing process.

Embossing and Debossing:

- Embossing: Raises designs or patterns on the surface of the tin lunch box.

- Debossing: Creates depressed areas on the surface for a textured effect.

Welding and Assembly:

- Spot Welding: Joins different parts of the tin box securely.

- Seam Welding: Creates a continuous weld for improved structural integrity.

Printing and Branding:

- Offset Printing: High-quality, detailed printing for intricate designs.

- Lithography: Suitable for large-scale production with consistent prints.

- Digital Printing: Ideal for short runs and customized designs.

Coating and Finishing:

- Rust-Proof Coating: Applied to enhance durability and prevent corrosion.

- Lacquering: Provides a protective layer and contributes to the visual appeal.

Die Making:

- Die Engraving: Creating precise molds for shaping tin components.

- Tooling: Involves the use of specialized tools for cutting, shaping, and forming.

Quality Control:

- Automated Inspection: Uses machinery for quality checks on dimensions and finishes.

- Manual Inspection: Skilled workers inspect for any defects or imperfections.

Environmental Considerations:

- Eco-Friendly Practices: Adoption of sustainable and recyclable materials.

- Water-Based Inks: Environmentally friendly inks for printing.

Automation and Robotics:

- Automated Production Lines: Streamline the manufacturing process for efficiency.

- Robotic Welding: Precision welding for consistent and reliable joints.

By incorporating advanced technologies, manufacturers can produce tin lunch boxes with consistent quality, intricate designs, and enhanced durability. The integration of automation and eco-friendly practices aligns with modern manufacturing standards.

Why Choose Us:

Experience: We boast extensive experience in the manufacturing of high-quality tin lunch boxes.

Customization: Our offerings include customization options, allowing for unique and personalized designs.

Quality Craftsmanship: We prioritize the use of high-quality materials and craftsmanship in every product.

FAQs bout tin lunch box:

Can I microwave a tin lunch box?

Yes, tin lunch boxes are microwave-safe.

Is it dishwasher safe?

Handwashing is recommended to preserve the printed designs and coatings.

How to clean and maintain the lunch box?

Clean with a soft cloth and mild detergent; avoid abrasive cleaners.

Can I get a customized design?

Absolutely, we offer customization for personalized designs.

Are there bulk order discounts?

Yes, we provide discounts for bulk orders; contact us for details.

What materials are used for construction?

Tinplate or other durable metal alloys are used.

Is it suitable for children?

Yes, our lunch boxes are safe for children; no sharp edges or harmful materials.

What is the typical delivery time?

Delivery times vary; contact our customer service for specific information.

Do you offer international shipping?

Yes, we offer international shipping with varying shipping costs.